The EPFU is the product that with small diameter, lightweight, highly flexibility and proper stiffness, and it can be blown into the microduct of 5.0/3.5mm. The Fibers are coated with a soft acrylate resin which provides excellent dimensional and thermal stability to cushion the fibers; in addition, the resin can be easily stripped in connecting the Fibers. The outer sheath is a thermoplastic that is of low friction. The surface of the sheath is designed with special grooves, compared to the surface of the traditional optical fiber cable; it provides not only the high level of mechanical protection, but also the perfect blowing performance.

Features and Benefits

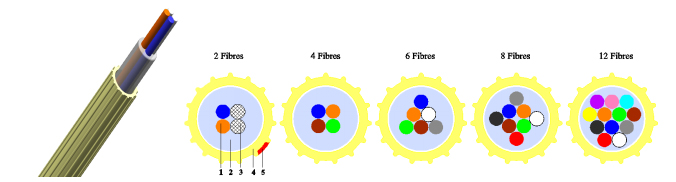

2、4、6、8 and 12 Fibers options.

Stable structure, good mechanical and temperature performance.

Designed with special grooves to advance blowing distance.

Lightweight and proper stiffness, repeat installation.

Designed with no gel, easy stripping and handling.

Better costs advantage compared to traditional product.

Complete accessories, less manpower, lower installation

Standards

Unless otherwise specified in this specification, all requirements shall be mainly in accordance with the following standard specifications.

Optical Fibre …...ITU-T G.652、G.657

IEC 60793-2-50

Optical Cable ……IEC 60794-1-2、IEC 60794-5

Technical Parameter

Fibre Unit Structure

Basic Performance

| Fiber Count | 2 Fibers | 4 Fibers | 6 Fibers | 8 Fibers | 12 Fibers |

| Outer Diameter(mm) | 1.15±0.05 | 1.15±0.05 | 1.35±0.05 | 1.50±0.05 | 1.65±0.05 |

| Weight(g/m) | 1.0 | 1.0 | 1.3 | 1.8 | 2.2 |

| Min Bend radius(mm) | 50 | 50 | 60 | 80 | 80 |

| Fiber type | G652D, G657A1 or G657A2 | ||||

| Temperature | Storage:-30℃ ~ +60℃ Operation:-30℃ ~ +60℃ Installation:-5℃ ~ +50℃ | ||||

| Note: It is recommended that the structure of 2 Fibers unit consist of 2 filled Fibers, for it is proved that 2 Fibers unit with 2 filled Fibers is better than the one with zero or one filled fiber in the blowing performance and the fiber stripping-ability | |||||

Testing parameter

Fiber Unit Attenuation

| Fiber Type | SM G.652D、G.657 |

| Attenuation | 0.40dB/km max @1310nm 0.30dB/km max @1550nm |

Blowing Test

| Fiber Count | 2 Fibers | 4 Fibers | 6 Fibers | 8 Fibers | 12 Fibers |

| Standard duct | 5.0/3.5 mm | ||||

| Pressure | 7bar / 10bar | ||||

| Typical blowing distance | 500m / 1000 m | 500m / 1000 m | 500m / 1000 m | 500m / 1000 m | 500m / 800 m |

| Typical blowing time | 10 min / 18 min | 10 min / 18 min | 12 min / 18 min | 13 min / 18 min | 15 min / 20 min |

Mechanical Performance

| Test | Standard | Parameters | Test Results |

| Tension | IEC 60794-1-2-E1 | Load is 1×W |

fibre strain ≤0.4% at MAX Additional attenuation ≤0.05dB fibre strain ≤0.05% after test |

| Bend | IEC 60794-1-2-E11A |

Diam 40mm×3turns 5 cycles at 20℃ |

Additional attenuation ≤0.05dB,after test |

| Crush | IEC 60794-1-2-E3 | 100 N, 60s | Additional attenuation ≤0.05dB,after test |

| All optical testing proceeded at 1550 nm | |||

Environment Performance

| Test | Standard | Parameters | Test Results |

| Temperature Cycle | IEC 60794-1-2-F1 | -30C, +60C,(2 cycles) |

Absolute attenuation ≤0.5dB/km,during test Additional attenuation ≤0.1dB/km, during and after test |

| Water Soak | IEC 60794-5 | 1000 hours in water,18℃~22℃ |

(Test after temp cycle) ≤0.07dB/km Change compared to start value |

| Damp Heat Cycle | IEC 60068-2-38 | 25C, 65C, 25C, 65C, 25C,-10C, 25C |

Absolute attenuation ≤0.5dB/km,during test Additional attenuation ≤0.1dB/km, during and after test |

| All optical testing proceeded at 1550 nm | |||

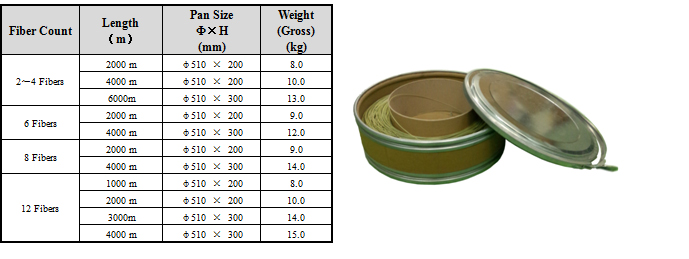

Ordering Information

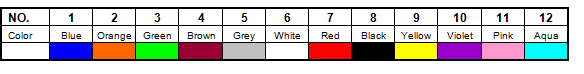

Fiber Color Code (fiber colors can also be determined by customer)

Sheath Color

Yellow

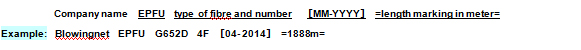

Sheath Marking

The outer sheath is marked in 1 meter intervals as follows:

Delivery Length

Standard delivery lengths are 1000m, 2000m, 3000m, 4000m, 6000m with a tolerance of -0.5~+1%.

For more options, please contact the customer service.

Packaging

Free coiling in the pan.